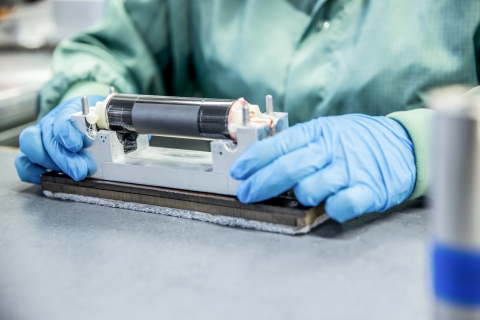

EAS lives innovation. Competence and know-how in cell and battery development have been growing at the Nordhausen production site for more than 25 years. In addition to its own product portfolio, EAS offers customised product developments, individual services and specific assembly services, accompanied by targeted consulting. In this way, EAS opens the innovation factory for external development processes, optimisation projects and manufacturing steps - from the electrode foil to the finished battery system including BMS.

Product development incl. BMS

EAS Batteries develops customized application solutions or individual innovation stages - right through to future-proof battery management systems (BMS). The EAS development service meets all electrical, mechanical and regulatory requirements for function, design, shape, format and weight of the new product across all industries.

Do you need customised battery packs, batteries, battery systems, battery management systems, cylindrical cells or individual components? We will be innovative for you. Send us an e-mail to sales@eas-batteries.com or simply call us: +49 3631 46703-0.

Evaluation

EAS examines, compares and assesses variants of individual cell or battery components including BMS. The reliable results of the evaluation determine, among others, whether a product is already suitable for production or whether a new, cheaper component works just as well as the previous one. The evaluation also answers questions about the improvement of product properties or which material is best suited for the application in consideration. EAS carries out evaluations independently as a neutral third-party provider.

You would like to optimise your product? Or position it better in competition? We can evaluate for you. Send us an e-mail to sales@eas-batteries.com or simply call us: +49 3631 46703-0.

Analysis and test

EAS proves existing products and materials using various chemical, physical and electrical test and analysis methods. Cells, batteries, battery packs or battery systems including BMS are examined with regard to their data sheet or the specifics of their intended use. With this service, EAS ensures quality and provides decision support for the selection of different suppliers. The cause of deviating behaviour, for example of the same active materials, can also be clarified and corrected in the laboratory.

You want to verify the properties of an existing product? We analyse and test for you. Send us an e-mail to sales@eas-batteries.com or simply call us: +49 3631 46703-0.

POJECT REFERENCES

OneD Battery Science: Cylindrical Cells with Silicon Anodes in 46900 Format

BMW Group: EAS accelerates development of cylindrical battery cells

South 8 Technologies: Pressure-stable lid for cylindrical cell with liquefied gas

Echion Technologies: Fast-charging cylindrical cell with niobium oxide anodes

FURTHER SERVICES

(Partial) production

- Components, prototypes and small series

- Assembly service for niche products, special batteries and cells

- Individual use of machine equipment (s. Equipment)

Certification service

- Cost- and time-optimised organisation

- Pre-evaluation

- Handling of formalities

Equipment and processes

- Mixer

- Double screw extruder

- Slitter

- Laminator

- Calander

- Winder

- Laser welding

- Automatic filling

- Formation and testing

- Cell cycling

- Battery cycling

- Electrochemical Laboratory

Consulting

- Safety of lithium-ion cells and batteries

- Cell development

- Battery development

- Battery management systems

- Evaluation, analysis, testing and feasibility studies

- Certification and declarations of conformity

Would you like to use the know-how and equipment of the Innovation Factory? With pleasure! Send us an e-mail to sales@eas-batteries.com or simply give us a call: +49 3631 46703-0.