The recycling of marine batteries is one of the most Important tasks of the maritime industry. What started about ten years ago with extremely small numbers in the electrification of shipping is leading to an exponential growth in recycling needs in about seven to ten years. "So far, not many marine batteries have reached their end of life," says Dr Klaus Brandt, battery technology consultant at EAS Batteries GmbH. "A separate and closed recycling loop therefore does not yet make sense for such a small number." But there are approaches that are already worthwhile - both economically and ecologically - in the design phase of ship batteries, for example the 3R principle. The three R's stand for "Reduce", "Reuse" and "Recycle". These guiding principles have also influenced the development of the safe, modular battery system for the maritime industry, EASy Marine®.

Reduce: intelligent use of materials and long service life

If you produce less, you must dispose of less. This basic principle of the R Reduce thus stands for the efficient use of resources. "That's the trick," says Dr Klaus Brandt. "The decisive factor is to use materials as intelligently as possible." In the case of a marine battery, this means using as little material per unit of power as possible. "EAS has achieved this with EASy Marine," says Dr Klaus Brandt. "The system produces the highest electrical power output per kilogram of battery of the systems in the marine market."

The service life is also crucial under the Reduce aspect - especially due to the intensive use of a ship's battery, for example for a ferry, of about 18 hours per day, 365 days a year. Investing in a long-lasting battery system is very sensible. And the longer it operates, the less often the issue of recycling arises. "A battery with LFP as cathode material achieves exactly this goal. EASy Marine therefore has a very long service life due to its cell chemistry," says Dr Klaus Brandt. "The cells are designed for 5000 full charge and discharge cycles. That corresponds to a service life of about ten years in continuous use."

Reuse: easy maintenance and continuous reuse

The efficiency claim of the second R goes beyond the basic idea of reduced material use: the aim of Reuse is to put already produced units, or even partial units, as often and for as long as possible into operation again. The modular battery system EASy Marine® supports this approach by providing an easy solution for the replacement of its LFP cells, which are long-lasting in themselves.

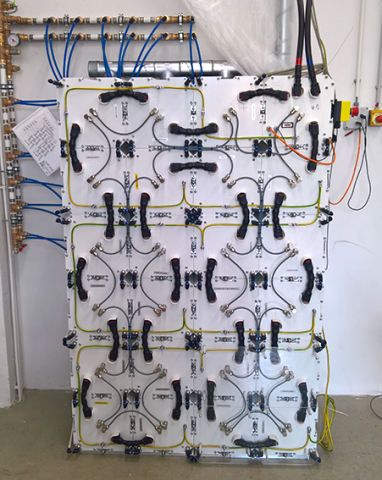

"Cells age differently. None is perfect," says Dr Klaus Brandt. "But you can replace a faulty cell within an EASy-Marine module very quickly and easy." An EASy-Marine® module contains 24 cells. They are mounted on the inside of the module's front panel. The battery management system (BMS) locates and reports a defective cell. "There are exactly five connections that the operator then has to undo to be able to pull out the cell block with the front panel, replace the cell and reattach the front panel to the module. After that, one reconnects the module using the five connectors and the battery is ready for use again." The replacement on board therefore only minimally affects the ship's operation. "The solution becomes really smart when the modules are connected in several strings to form a large battery system. This would be the case if the battery had a total energy content of around 200 kilowatt hours or more. The string with the defective cell could simply be switched off, while the other strings continue to operate the ship.

At the end of the useful life of the cells in the EASy Marine® battery system, they can be replaced several times. This means that the other parts of the ship's battery, such as the casing, cooling, and cabling, are preserved for a second, third or even further life - in the spirit of reuse. The cells, on the other hand, are taken back by the manufacturer and fed into the third R process, the actual recycling, by EAS.

Recycle: recovering ecologically and economically valuable materials

The recycling of lithium-ion cells is a complex process. Today, metals are mostly recovered in a metallurgical process at high temperatures, but not all components of a cell can be recycled today. "There are many research and development projects underway for the recycling of lithium-ion cells, there is still a lot to do," says Dr Klaus Brandt. "It is important for recycling to be able to separate components from each other in advance." EASy Marine® fulfills this requirement for the highest possible recycling rate of materials.

The components of the EAS marine battery can be easily separated from each other. The aluminium casing is either reused or the aluminium is recycled. The electronics can also be easily removed from the module and reprocessed separately. The copper of the connectors is also simple to remove. "This separation into individual components is a great advantage, for example compared to the complex batteries for electric cars," says Dr. Klaus Brandt. "In particular, one can recover metals or metal compounds that are expensive well with today's methods and bring them back into the cycle." However, processes that make recycled components such as electrolyte, anode or cathode as such available for cell production are not yet technically mature. "There is still a lot to be done. The legislator will probably have to issue the appropriate regulations first."

From an ecological point of view, one aspect of the recycling of maritime ship batteries is doubly important: the reduction of CO2 emissions in the extraction of their raw materials. For example, the production of aluminium is extremely energy-intensive, and the same applies to the processing of copper. "I can therefore significantly reduce the CO2 footprint of my battery if I reuse these metals instead of materials extracted from newly mined ores," says Dr. Klaus Brandt. "This is important from the point of view of conserving scarce resources alone." So here the third R leads back to the first R and closes the circle of Reduce, Reuse and Recycle.