Fourteen companies have joined forces to drive forward the hybridisation of European fishing fleets. They are recombining existing technologies and optimising them to create a holistic system that will enable smaller vessels to be converted in an economically viable way - in favour of low-emission and energy-efficient shipping. The ‘REFEST’ project is funded by the EU Programme for Research and Innovation ‘Horizon Europe’ and will run for 42 months. The kick-off meeting of the participating companies will take place at the end of May in Klaipeda, Lithuania.

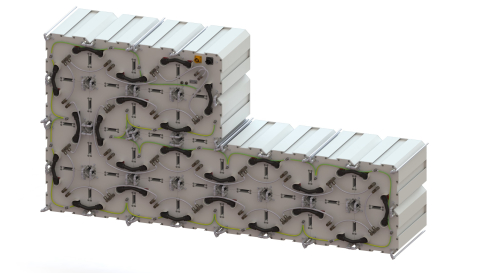

EAS Batteries is contributing to the REFEST project by developing a marine battery based on the modular ‘EASy Marine®’ battery concept. ‘We are looking in particular at alternative materials,’ says EAS Head of Sales Dr Frank Diehl. ‘And on which elements and components we can additionally optimise with regard to the project requirements.’ The aim is a safe, cost-efficient and lightweight lithium-ion battery system with a long service life in cold operating environments. The additional requirement is a high proportion of reusable and recyclable components. EAS is focussing on a high proportion of thermoplastic composite materials for the first time. ‘Plastics are lighter and cheaper than metal,’ says Dr Frank Diehl. “It will be exciting to explore how well the composite materials can be recycled.”

Converting existing ships to hybrid propulsion is a financial challenge. This applies to both the procurement and the operating costs. ‘In the end, it's always an economic equation that decides whether to convert,’ says Dr Frank Diehl. This is precisely where the consortium partners step in - with the overarching goal of reducing fuel consumption and greenhouse gas emissions by up to forty per cent. To achieve this, the REFEST project combines the most promising scalable technologies that are characterised by low investment costs, simple integration and the improvement of the energy efficiency of traditional fishing vessels.

‘We think about the scalability of the marine battery right from the design stage,’ says Dr Frank Diehl. ‘The EASy Marine concept fulfils this requirement, as it is a system with few basic components that are already trimmed for cost efficiency. Easy Marine functions as a flexible technology platform that achieves cost-cutting effects both at production level and in the purchase of materials with increasing quantities.’ This potential can be realised both in the planned application of a large number of small vessels or transferred to larger ships.

The scaling aspect is also attractive for the consortium partners themselves. They can build up environmentally relevant technologies and the corresponding expertise in Europe and then export them. ‘There is huge potential in such projects. New markets are emerging for the companies involved, who want to further develop and utilise their technologies, and Europe would remain independent in this segment,’ says Dr Frank Diehl. ‘In addition, the intra-European exchange opens completely new perspectives. It creates unexpected points of contact with other technologies and, in turn, synergies that can lead to completely new approaches. We are therefore very much looking forward to working with our new colleagues from all over Europe.’