EAS Batteries will present the EASy Marine® battery system at the Posidonia international shipping exhibition in Athens from 6 to 10 June 2022. The reason: Greece's maritime market is becoming greener. "This is a process that the Hellenic Republic is consciously driving," says Dr Frank Diehl, Head of Sales and Marketing at EAS Batteries. The change is already noticeable in the shipping industry. Understanding in the Greek market for green propulsion is growing. "We are experiencing the openness and increasing awareness of the importance of a more sustainable maritime industry in Greece through the close cooperation with Euploia, our local partner. This is a development that we are doing our very best to support."

Zero-emission entry into ports is becoming increasingly important across Europe. Market observers expect regulations in this regard to be introduced in Greece within a few years. Ship operators are therefore already being called upon to prepare their Greek fleets for the future. The solution lies in electric or hybrid-electric ship propulsion.

Beyond zero-emission propulsion, EAS Batteries has made it its mission to make green shipping safe for crew, passengers and cargo. That's why its modular battery system for the maritime industry, EASy Marine®, is based on the maximally safe cell chemistry lithium iron phosphate (LFP). "Here we are acting true to our claim 'Power you can trust,'" says Dr Frank Diehl. "The battery may get hot in the event of a short circuit, overcharging or mechanical damage to the cell, but it will not start to burn on itself." This cathode cell chemistry is considered a benchmark in safety.

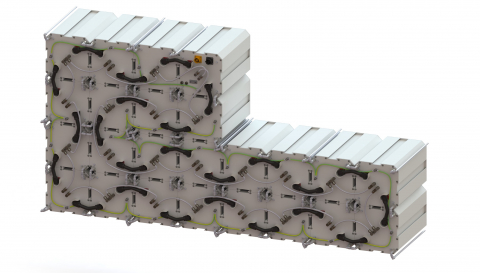

The marine battery EASy Marine® is particularly suitable for converting existing ships to hybrid electric mobility. The modular space concept of the battery system enables almost any ship owner to convert his propulsion system to a fuel-optimized hybrid system. The reason: the design of the battery can be adapted to almost any ship architecture. "It's like Lego for adults," says Dr Frank Diehl. The modules can be flexibly combined. "EASy Marine modules can even be used to replicate steps, so that in fact sloping walls no longer pose a space problem." Thus, with EASy Marine®, even intermediate spaces as well as rooms with low ceilings or deviating floor plans can be used for the electrification of a ship. This modular design of the battery system is unique in the maritime industry.

The general advantage of an on-board battery system like EASy Marine® is that diesel generators can be operated permanently in the so-called sweet spot, where fuel consumption is lowest relative to the power generated. In addition, the batteries compensate for load fluctuations, for example in propulsion or hotel loads. This is known as peak shaving or load leveling. Depending on load fluctuations, savings of up to 25 or even 30 percent are possible in this way.

But propulsion systems based on diesel, LNG or fuel cells are not only operated more economically with the help of a marine battery, their service lifes are also extended. With EASy Marine®, EAS Batteries is thus helping to safely electrify shipping and make it more efficient at the same time. EASy Marine® is already DNV certified.

"EASy Marine is an absolutely convincing battery concept," says Manos Tsonis, Sales Executive of Euploia Drydocks & Services Ltd. "The marine battery is innovative, flexible and safe. Thus, EAS helps the Greek maritime market with a German-European product to sustainably strengthen its core business and to future-proof it."

EAS Batteries develops and produces cells and batteries in Germany, with materials from Europe. "With EASy Marine, we offer an autonomous battery system for the global shipping market that is independent of other continents and based on German technologies," says Dr Frank Diehl. "This is a strong solution that ensures reliability at different levels - in operation, in the supply chain, in quality and in sustainability."

The particular advantage of EASy Marine® is that the battery system permanently and directly benefits from the further development of cell technology. EAS Batteries continuously improves its cell portfolio and installs the latest technology in the marine battery.

"In the next steps, we will also diversify and expand our EASy Marine offering itself," says Dr Frank Diehl. "Safety on the water will always be our focus." Based on current knowledge, LFP remains the safest active material that can be used in battery cells in the long term. And already at this level of the marine battery, the properties combine to be safe, green and efficient: LFP is not only the safest material, but also the most sustainable. Iron and phosphorus - unlike cobalt, nickel or manganese - are not scarce resources. LFP has a significantly lower carbon footprint in production. And the lithium itself is used more efficiently in this combination. The scarcity of other materials will drive up their price in the global effect. "Given the coming CO2 price, this will also make LFP cheaper in the long term," says Dr Frank Diehl. "In principle, however, the EASy Marine modular battery system functions independently of the cell chemistry of the installed cells and automatically adapts to future developments."